Fully Automated Dissolution System RoboDis II+ Technical Data

| Weight | 760 kg, note floor load capacity |

|---|---|

| Dimensions Housing, Transport (H x W x D) | 1800 x 2020 (total) x 1020 (total) mm |

| Dimensions Housing, Installation (H x W x D) | 2800 x 2020 (total) x 1300 mm |

| Power supply: Type | Tri-phase four-conductor system (L1-L3/N/PE) |

| Operating voltage | 400 VAC, 50/60 Hz |

| Control voltage | 24 VDC |

| Power rating | approx. 5.2 kW |

| Fuse | 32 A |

| Water | Connections for cleaning and demineralized water max. 5 bar (0.5 Mpa) set to approx. 3-4 bar for MediPrep max. 60 °C Connection for 1/2-inch hose |

| Connection for waste water with low contamination level | Connection for 3/4-inch hose |

| Connection for waste water with high contamination level | Connection for 3/4-inch hose |

| Height of the waste water connections | Max. 20 cm above the ground |

| Connection for media tank | Norprense® hose ID 1/4-inch |

| Doors | Two-leaf, makrolon, transparent, safety lock |

| Robot Supplier | Festo |

| Model | RP (room portal) |

| Frame material | Aluminium |

| Operating range | 1420 mm x 540 mm x 600 mm (xyz) |

| Interfaces (control) | ModBus TCP/ EtherCAT |

| Interfaces (configuration) | Standard Ethernet LAN |

| Angle of rotation | 180° (electrical rotary drive) |

| Robotic tools | Filling and cleaning tools, pH probe |

| Number of testers | 1 |

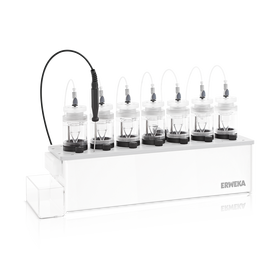

| Test stations | 7 in a row |

| Test station connections | With toothed belt and gear wheel |

| Agitators (shaft and stirring elements) | Stainless steel 1.4571 (316Ti) |

| Stirring element | Paddle (standard), basket (optional) |

| Operation | DC motor with speed sensor, sequential agitator switch (stepper motor) |

| Vessel | Glass (borosilicate) |

| Evaporation | Less than 1% in 24 hours |

| Time measurement | Time in realtime, tolerance ± 1 sec. |

| Temperature measurement | PT 100 sensor |

| Temperature in the vessel | 37 °C ± 0.5 °C; temperature range +4 °C (RT) to 40 °C ± 0.5 °C |

| Stirring speed | 25 min ± 2 min up to 200 min ± 4 min |

| Water bath | Acrylic glass |

| Water bath volume | Approx. 30 l |

| SPS | CodeSys Version 3.5 |

| Other connections | PT 100 connection, heating connection and interface |

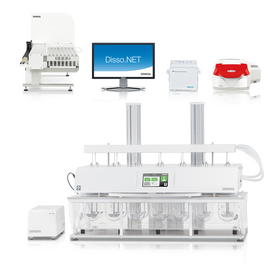

| Control/operation | Controller, monitor, keyboard, mouse, WIN software |

| Software | ERWEKA Disso.NET software, video software |

| Heating system | Flow-through, type ERWEKA DH 1520 |

| Heating capacity | 1500 W |

| Flow-through speed | 6 l/min |

| Interface | RS 232 |

| Automatic production/degassing/heating | MediPrep (ERWEKA) |

| Production | Made from up to 6 concentrates + de-ionised water or pre-mixed medium; Vmax MediPrep: 8000 ml |

| Degassing | Vacuum > 190 mbar absolute |

| Heating | Flow-through heating 1500 W, max 40 °C |

| Scale | SST with load cell |

| Pump type | Piston pump, ceramic head |

| Pump Interface | RS-232 |

| Vessel filling | 250 ml - 1000 ml +- 1% (volumetric filling) |

| Magazines, basket | Two, each with 6 x 10 rows - USP Method 1 (only for 40-batch) |

| Magazines, tablet holder | Tablet size max. ⌀ 35 mm |

| HPLC device | max. 2 HPLC systems |

| Automatic filter changer (opt.) | AFC (ERWEKA) |

| Flow-through cuvette (opt.) | 1-10 mm |

| Cleaning: Suction pump | CP 7+ diaphragm pumps |

| Cleaning: Flow-through | Approx. 1000 ml/min |

| Cleaning: Hoses | Norprene® |

| Protection type | I/EN 61140 |

| Protection class | IP 21/IEC 529 |

| Ambient temperature in operation | +10 °C to +30 °C (ambient temperature at least 5 °C lower than test temperature) |

| Storage and transport temperature | +5 °C to +40 °C |

| Relative humidity | 25 to 80 % non-condensing |